|

The Great Falls

Power House - Introduction

Oil and Gas in

the Caney Fork Basin

Oil seeps were known to some of the early

settlers. Geo. J. Stubblefield purchased oil leases from

Robert Davis in Big Bottom and others in 1865.

Geo. W. Colbert bought oil leases on Caney Fork near Cane Creek

in 1877 and also rights for a pipe line.

At least one oil well was drilled above Hodge Bridge.

A number of wells were drilled in the Collins River Valley south

of McMinnville but no flow of gas or oil of any quantity was

ever found.

When test holes were drilled for the Great Falls Dam in 1915 a

small amount of oil was discovered. There was a very small flow

of gas from a rock crevice about 300 feet below the Power House

in the late 1920's. The writer lighted it with a match on a

number of occasions. The flame was not more than 3 inches long.

|

Hydro-Electric Power

Plants

| |

|

Burgess Falls

on Falling Water Creek - A dam was constructed at this

location to provide a reservoir |

for both a water supply

and electric power for the City of Cookeville. Its prime

purpose at this date, 1972, is to provide storage for

the water system.

|

| Center Hill

Dam and Reservoir on the Caney Fork River at Mile

26.6 - This project was built by |

the Corps of Engineers, U.S.

Army, Nashville Office for flood control on the

Cumberland and lower rivers, generation of electric

power, and at the same time provides many recreation

facilities for Middle Tennessee. When the reservoir is

full the water is backed up to the tail-water at the

Great Falls Power House. For detailed information

on this project consult publications issued by the

Corps. [See the

1942

map for the map of the

area where the Center Hill reservoir was later located.]

|

|

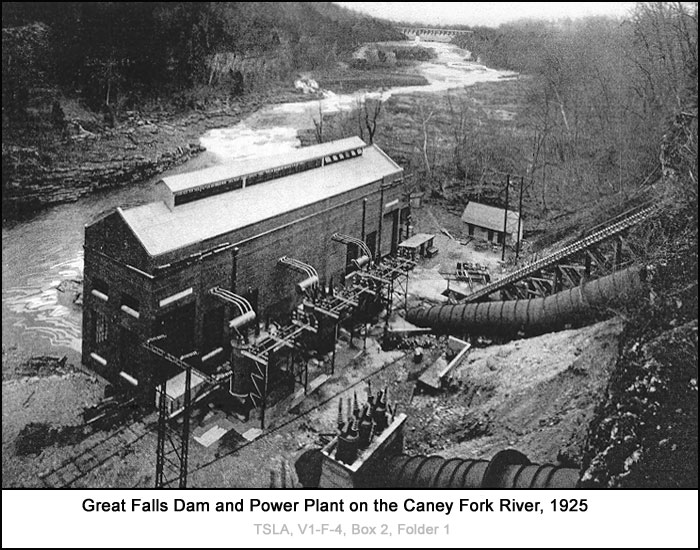

Great Falls Power

House and Dam

on the Caney Fork River - For the first chapter in the |

development of power at Great Falls see

"Bosson Mill" and for the second chapter see "Falls City

Cotton Mill." The first two developments made use of a

very small part of the water power available and that

for small mills in each case.

Back in 1898 Arthur J. Dyer of Nashville

and a founder of the Nashville Bridge Company began

reconnaissance surveys on the Caney Fork River with a

view of developing a future water supply for the City of

Nashville. It was not long before he realized the power

possibilities at Great Falls. He took an option in May

1901 [?] on the land on the north or White County side

of Great Falls. On March 13, 1902 [?] the Great Falls

Power Company was incorporated with a capital stock of

$20,000 and in May of the same year the option secured

by Mr. Dyer was purchased. Charles H. Fiske, the

engineer, Mr. Newman of Detroit who furnished the first

money, Fielding H. Yost, W.M. Goodlett, Dan E. McGugin

and Thos. G. Kittrell all played an important part in

the early development of Great Falls as a hydroelectric

plant.

Very little was done in securing riparian

rights till 1904. From that date on all the old mill

sites were purchased. Practically all of the mills

within the area of the proposed development had been

destroyed in the flood of March 1902. By 1909

considerable property had been acquired and during the

previous year the Charter was amended providing for

additional stock.

The Search for New

Capital

The early promoters now began looking about for new

capital. E.W. Clark & Company took a thirty-day

option on the property but at the end of the month a

package arrived at the depot which proved to be the

abstracts which had been returned thus dashing the hopes

of Mr. Dyer and his associates. In the meantime

the Great Falls Power Company had used the option money

to purchase additional real estate. It should be

mentioned that Mr. E.L. Tyndale of Sparta prepared the

hundreds of abstracts on the properties purchased.

They served as a wonderful source of information to the

writer on old names, roads, mills, people and other

items of historical interest.

The

Bylessby Company Enters the Picture

It was not

long before H.M. Bylessby & Company of Chicago took a

thirty day option but like the Clarks they did not keep

it. Still more property had been purchased with

the money received from Bylessby. The outlet

[outlook?] was

anything but bright, but it so happened that both the

Clark and Bylessby interests were interesting themselves

in the property of the Nashville Railway & Light

Company. When things looked most gloomy both companies

again asked for an option on Great Falls and it was sold

to the Bylessby Company who a short time later purchased

the controlling stock in the Great Falls Power Company.

On April 24, 1912 the Tennessee Power Company was

incorporated, which corporation purchased the Great

Falls Power Company and began buying land on a large

scale and preparing plans for the development. At

the same time surveys were started of the entire

reservoir area. Jim Baker claims to have opened up

the 300 foot chain for the first time and helped make

the first measurement with it.

The Original

Design Was Not Used

It is

interesting to note that the original plans called for a

dam 110 feet high. At the "Narrows," where the two

tunnels are now located, an open cut was to be made from

the Collins River to the Caney Fork. The water was

to be carried across the Caney Fork in a steel flume and

then in an open canal across Horseshoe Bend, a distance

of 1.5 miles. The Power House was to be located on

the right bank of the river near Sulfur Spring three

miles or more by river below the present Power House.

In so doing a total head of 235 feet would have been

available; 110 feet at the dam, 75 feet between the dam

and the present Power House and 50 feet around horseshoe

bend. Plans were made for high level bridges

across the pool and the necessary contracts secured from

the three counties involved.

Bylessby

Starts Work on the Project

In 1912 the

H.M. Bylessby Company put a force of 500 men in the

field and actually began construction of cofferdams and

excavation for the dam but within 30 days the Caney Fork

swept away the cofferdams and all work was suspended and

then definitely stopped.

The Bylessby Company had in the meantime made an

unsuccessful attempt to gain control of the Nashville

Railway and Light Company. E.W. Clarke & Company

succeeded. As Great Falls was worthless without a

market for the power the Bylessby people sold their

stock in the Tennessee Power Company to the Clarkes and

at the same time made a contract to construct the

transmission line from Cleveland Junction to Nashville

by way of Great Falls. The line was built in 1912

and 1913. Charlie Evans was employed in 1912 as

the first patrolman on this line. He lived at Rock

Island and walked and rode in a buggy over the line for

the next 25 years.

The First Plant Is

Built

Things moved slowly for a few years until December

1915 when word went forth that actual construction of a

40 foot high dam was to begin immediately. Roads

were built, a camp established and work pushed rapidly.

Within a year the dam had been built, a tunnel driven

through the "Narrows" and a power house constructed of

sheet metal and one generating unit installed with a

capacity of 12,000 horsepower. R.H. Anderson or

"Cap" Anderson, as he was affectionately known to his

men, was in charge of the work. The plant was

placed in operation January 1, 1917.

Capacity Is Tripled

The name was

changed in 1922 to The Tennessee Electric Power Company,

TEPCo. The use of electricity grew rapidly and as a

result Cap. Anderson, Chief Engineer and C.E. Ayre,

General Superintendent, again built a camp, gathered a

crew and began work in the late spring of 1923. The dam

was raised 35 feet, a second tunnel was driven through

the "Narrows, a new 20,110 horsepower generating unit

was installed and the old unit increased to 15,400

horsepower, a new brick Power House erected, the

reservoir cleared, nine bridges raised and lengthened

and nine new bridges built. The work was completed in

April, 1925 but the reservoir was not filled until

October of that year.

[Note: This photo is from

Mr. Crouch's materials at TSLA in Nashville, but does

not appear in his book.]

Great Falls

|

- 1925

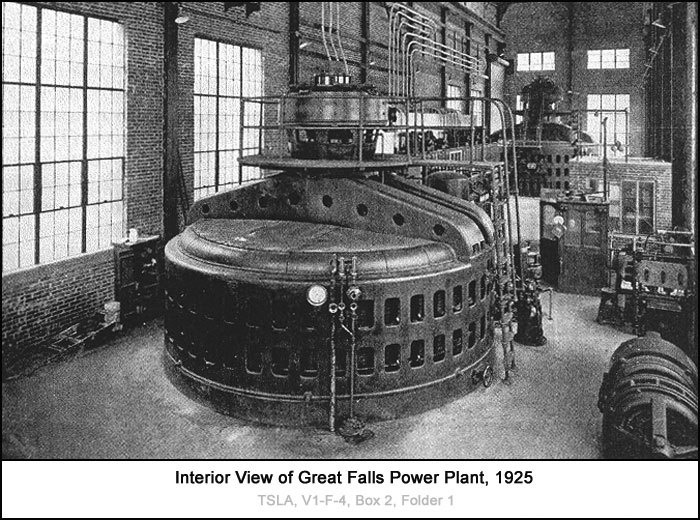

Article Associated with the Two Great Falls

Photos Displayed Here -

The Great Falls

development was commenced on December 7,

1915, near the town of Rock Island in Middle

Tennessee, 75 miles southeast of the city of

Nashville. A short distance below this

town the Collins River and just below their

confluence a gravity type dam was erected

across the Caney Fork. This dam built

of cyclopean concrete was at the time of

construction 740 feet long and 56 feet high,

with a spillway section of 540 feet and

surmounted by a 14 foot roadway throughout

its entire length. Just below the dam

there is a natural fall in the Caney Fork

River and the power house was constructed

below the "Great Falls" to utilize the

advantage of the additional head.

Another unusual condition exists at this

development in that the Collins River

parallels the Caney Fork for some distance,

separated only by a narrow mountain ridge,

with the streams flowing in opposite

directions. Advantage was taken of

this condition in the building of a concrete

lined tunnel, 13 feet square and 490 feet

long, from the Collins River through the

ridge to the Caney Fork. The

combination of the dam and natural falls

gave a head of 110 feet for the single

13,000 horsepower vertical turbine installed

in the power house.

Work on this development

was completed in December, 1916.

Altogether, 22,500 cubic yards of concrete

were used in the dam structure and 7,900

cubic yards of rock excavated for the

tunnel. The latter discharges into a

steel penstock, 12 feet in diameter and 174

feet long, that carries the water to the

power house. Equipment is of

Allis-Chalmers manufacture. The single

runner hydraulic turbine, rated at 13,000

horsepower, is connected to a 9375 kva

generator operating at 6,600 volts and 180

revolutions per minute.

In the spring of 1923 The

Tennessee Electric Power Company, in order

to provide for the ever increasing demands

for electricity, began the construction of a

23,360 horsepower addition to the Great

Falls plant. This work involved

building 35 feet more height onto the

existing dam, making the available head 150

feet, the drilling of a second tunnel

through the mountainside, and the building

of a new brick and steel power house to

replace the temporary structure erected in

1916. Work on this project was carried

on during 1923 and 1924 and the new turbine

was placed in service at the old operating

head in October, 1924. The original

unit was then removed from service to permit

the rebuilding of the tunnel intake so as to

conform to the new head water conditions.

The work of closing the dam was completed in

March, 1925. Some idea of the

magnitude of this undertaking may be gained

from the fact that the raising of the dam

and consequent flooding of land necessitated

the elevating or building of fifteen highway

and one railroad bridge, the farthest of

which was located 25 miles upstream.

The Great Falls reservoir now covers an area

of 2,250 acres and has a storage capacity of

6,000,000 kilowatt-hours, as compared with

900 acres and a storage of 648,000

kilowatt-hours formerly.

Source: "Organization, Development,

Forecasts for Future through Using Water

Power," 1925 article from a magazine

published by The Tennessee Electric Power

Company. Available at the TSLA in

Nashville, TN: V1-F-4, Box 2, Folder 1. |

[Note: This photo is from Mr. Crouch's materials at TSLA

in Nashville, but does not appear in his book.]

The Flood of 1929

Twenty seven years

had passed since the flood of Good Friday 1902. On

Good Friday 1929, following torrential rains feeding the

hundreds of tiny rivulets in the mountains as well as

the flat country drained by the Barren Fork River,

caused the Caney Fork River to go on a rampage such as

had never been known. The angry waters, sweeping

bridges, buildings, timbers and trees with them, swept

down towards Great Falls. The reservoir level rose

above the wing walls of the dam but it stood the test.

The Power House was flooded and the substation damaged

but for the first time the old river had met its master.

The Men Who

Operated the Plant

Fred Adkins, the

first Superintendent, was on hand when the plant started

operation on January 1, 1917. In the fall of 1918

Sam K. Thompson took charge and in the latter part of

1927 he was succeeded by W.P. Roddey. Robert (Bob)

Hash had the longest operating service record, having

served as operator and chief operator continuously since

the plant started up to the time this was written in

1933. Mr. Adkins became Superintendent of all

hydro-electric plants after leaving Great Falls.

The Men

Who Built the Plant in 1923-25

The names of the

Engineers, Office Force, Foremen, Craftsmen and Helpers

who worked on the project between 1923 and 1925 are

listed on the following pages. They came from

Tennessee, Alabama, South Carolina, Virginia, Georgia,

Illinois, Pennsylvania, and New York.

Titles and rates of pay have been included to give the

reader some idea of relative rates for the various jobs.

The common labor rate started at $0.25 per hour when the

job began but was raised to $0.275 per hour within six

months. This compared with $0.10 to $0.15 (per

hour) paid locally.

Farmers with mules were paid $0.50 per hour for a driver

and team. All work was on a 10-hour day.

Four to six teams were used on a heavy 10-ton wagon used

to haul heavy equipment. A 20-mule team was used

to move the water wheel and generator from the Depot to

the plant on rollers.

The Skilled Workers Who Built the Great Falls Power

Plant

| Name |

Occupation |

Rate |

Home - Tenn. Unless Shown |

| |

|

|

|

|

Able,

W.E. |

Carpenter |

.50 |

DeRossett |

|

Addison, A.D. |

" |

.50 |

Chickamauga, Ga. |

|

Alspaugh, J.H. |

" |

.50 |

Stevenson, Ala. |

|

Anderson, E.A. |

" |

.50 |

Rossville, Ga. |

|

Anderson, P.L. |

Pipe

Fitter |

.30 |

Walling |

|

Arnold, H.A. |

Carpenter |

.40 |

Smithville, Route 9 |

|

Arnold, W.I. |

" |

.40 |

Smithville |

|

Ault,

D.H. |

" |

.50 |

Cleveland |

| |

|

|

|

|

Baker,

J.C. |

Pipe

Fitter |

.35 |

Walling |

|

Baker,

J.E. |

Rodman |

$3 Day |

Rowland, Route 1

Fine |

|

Barnes, J.L. |

Carpenter |

.45 |

Copper

Hill |

|

Barnett, E.E. |

Rigger-Carpenter |

.35 |

Rock

Island |

|

Barnett, J.P. |

Blacksmith |

.50 |

Cowan |

|

Barnett, Wheeler |

Compressor Oper. |

.35 |

Walling |

|

Bealdsoe, W.L. |

Mechanic |

.50 |

Chattanooga |

|

Bell,

L.W. |

Driller |

.45 |

Copper

Hill |

|

Bell,

M.M. |

Drill

Helper |

.35 |

Culberson, N.C., Route 2 |

|

Bell,

J.C. |

Driller |

.45

|

Duck

Town |

|

Bellew,

H.M. |

" |

.45 |

Copper

Hill |

|

Berger, J.L. |

Hoist

Oper. |

.30 |

Copper

Hill |

|

Blackburn, J.C. |

Carpenter |

.50 |

Morrison |

|

Boling, L.A. |

Hoist

Engineer |

.50 |

Benton |

|

Bowls,

B.M. |

Carpenter |

.45 |

Sparta |

|

Brazer,

Willis |

" |

.50 |

Morrison |

|

Breding, W.A. |

Hoist

Engineer |

.50 |

Benton |

|

Breedlove, C.E. |

Carpenter |

.35 |

Rock

Island |

|

Brown,

I.B. |

Pipe

Fitter |

.30 |

Twinton |

|

Brown,

Mark |

Dinky

Engineer |

.40 |

Ocoee |

|

Broyles, J.F. |

Carpenter |

.50

|

Sparta |

|

Buice,

Raymond |

Driller |

.45 |

Copper

Hill |

|

Bumpus,

J.W. |

Rigger

|

.40 |

Cleveland |

|

Burnett, J.D. |

Driller |

.45 |

Copper

Hill |

| |

|

|

|

|

Cantrell, J.W. |

Carpenter |

.40 |

Smithville |

|

Carmack, C.L. |

Office

Mgr. |

|

Chattanooga |

|

Carter, Charlie |

Rigger |

.45 |

Walling |

|

Carter, D.E. |

Electrician |

.35 |

McMinnville |

|

Carter, Wallace |

Rigger |

.35 |

Walling |

|

Carter, W.C. |

Driller |

.45 |

Copper

Hill |

|

Cates,

Grover C. |

Gen'l.

Carp. Form. |

.80 |

Ocoee |

|

Cates,

Marvin |

Carpenter |

.50 |

Ocoee

(& Truck Foreman) |

|

Center, William |

Time

Keeper |

|

Copper

Hill |

|

Chambers, L.H. |

Store

Room Keeper |

150 |

Cleveland |

|

Chisam, W.A. |

Electrician |

.45 |

Walling |

|

Christianson, Wm. |

Carpenter |

.50 |

Gilman, Ala. |

|

Clark,

Doc |

Carpenter Helper |

.35 |

Walling |

|

Cloer,

C.L. |

Mechanic |

.50 |

Epworth |

|

Cochern, Edgar |

Rigger |

.40 |

Fort

Payne, Ala. |

|

Cockrell, K.C. |

Carpenter Foreman |

.70 |

Magee,

Miss. |

|

Combow,

J.E. |

Carpenter |

.40 |

Cleveland |

|

Copeland, John |

Carpenter |

.50 |

Chattanooga, 4119 42nd. Ave. |

|

Cotton, A.P. |

" |

.40 |

Walling |

|

Crouch, A. Weir |

Transitman |

|

175

East Aurora, N.Y. |

|

Cotton, C.B. |

Blacksmith Helper |

.35 |

Rock Island |

|

Couch, W.B. |

Driller |

.50 |

Benton

(Assist. Foreman) |

|

Counts, W.L. |

Carpenter |

.50 |

Elora |

|

Crawford, M.A. |

Lineman Helper |

.30 |

Rock Island |

|

Crawford, Tullos |

Mach. Helper |

.40 |

Rock Island |

|

Cruse, J.D. |

Rigger |

.40 |

Rock Island |

|

Cruse, R.K. |

Carpenter |

.30 |

Doyle |

| |

|

|

|

|

Daves, J.R. |

Carpenter |

.50 |

Copper Hill |

|

Davis, W.W. |

Hoist |

.50 |

Rock Island |

|

Dedrick, G.S. |

Carpenter |

.50 |

Doyle |

|

Denton, E.C. |

" |

.50 |

Quebeck |

|

Denton, E.M. |

Pipe Fitter |

.30 |

Quebeck |

|

Deaton, D.C. |

Blacksmith Helper |

.30 |

Quebeck |

|

Dilbeck, W.W. |

Blacksmith |

.60 |

Blue Ridge, Ga. (A1) |

|

Dodson, G.W. |

Carpenter |

.50 |

Eastland |

|

Donaldson, G.A. |

Carpenter Forem. |

.65 |

Elora |

|

Duncan, E.P. |

Driller |

.45 |

Quinton |

|

Duncan, L.H. |

Carpenter |

.40 |

Campaign |

|

Dunham, Frank D. |

Saw Filer |

.50 |

Walling (Blacksmith) |

|

Dunlap, Simp |

Rigger |

.50 |

Rock Island (Driver) |

| |

|

|

|

|

Eldridge, C.L. |

Carpenter |

.40 |

Sparta |

|

Ellis, J.A. |

" |

.50 |

Rossville, Ga., 457

Chickamauga Ave. |

|

Eslick, C.H. |

" |

.50 |

Mulberry |

|

Eyler, Harry |

Gen. Labor Forem. |

.80 |

Rock Island & Everywhere |

| |

|

|

|

|

Finnel, Ira |

Carpenter |

.50 |

Cleveland |

|

Finney, W.R. |

" |

.50 |

Tullahoma |

|

Fisher, Eston |

Machine helper |

.40 |

Walling |

|

Foote, C.E. |

Plummer |

.45 |

Cleveland |

|

Freemen, T.C. |

Air Compressor |

.35 |

Rock Island (R.R. Engineer) |

|

Fralley, A.L. |

Derrick |

.60 |

Rossville, Ga. |

|

Franklin, M.W. |

Carpenter |

.40 |

Rock Island |

|

Franklin, O.K. |

Rigger Forem. |

.80 |

Benton |

|

Franks, J.B. |

Carpenter |

.50 |

Quebeck |

|

Fulmer, Paul |

Stenog. |

110 |

Centerville |

| |

|

|

|

|

Geer, L.L. |

Quarry Forem. |

.60 |

McMinnville |

|

Gilbert, E.C. |

Rigger |

.35 |

McMinnville |

|

Gilbert, W.R. |

Pipe helper |

.30 |

Rock Island |

|

Gillian, T.D. |

Carpenter |

.50 |

Chattanooga 1024 - 11th. St. |

|

Goforth, J.L. |

Pipe Fitter |

.30 |

Benton |

|

Green, E. |

Rigger |

.40 |

Campaign |

|

Green, E.D. |

Carpenter |

.35 |

Quebeck |

|

Green, G.J. |

Mechanic |

.60 |

Greer, S.C. |

|

Green, J.H. |

Carpenter |

.40 |

Walling |

|

Green, J.T. |

Carpenter Forem. |

.55 |

Rock Island |

|

Green, W.M. |

Labor Foreman |

.70 |

Sheffield, Ala. |

|

Greer, J.R. |

Carpenter |

.50 |

Copper Hill |

|

Griffin, R.V. |

Hoist Runner |

.60 |

Benton |

|

Grissom, R.J. |

Carpenter Forem. |

.65 |

Quebeck (Excellent) |

|

Gross, W.R. |

Carpenter |

.50 |

Walling |

| |

|

|

|

|

Haggard, Ellis C. |

Payroll |

150 |

Cleveland |

|

Hannley, C.E. |

Elec. helper |

.35 |

Doyle |

|

Halteman |

Blacksmith |

.60 |

Quebeck |

|

Hamilton, R.H. |

Carpenter |

.50 |

Quebeck |

|

Haston, R.L. |

" |

.35 |

Rock Island |

|

Haston, H.C. |

Blacksmith |

.60 |

Sparta (Very Good) |

|

Henry, W.S. |

Carpenter Forem. |

.75 |

Chattanooga, 4207 Ave. F |

|

Hicks, N.P. |

Carpenter |

.50 |

Boyles, Ala. |

|

Hinch, W.H. |

" |

.50 |

Winchester |

|

Hitchcock, H.E. |

" |

.50 |

Rock Island |

|

Hodges, E.H. |

Pipe Fitter |

.30 |

Cummingsville |

|

Hodges, T.M. |

Carpenter |

.50 |

Doyle |

|

Howard, Hosey |

Lineman |

.30 |

Rock Island |

|

Huckabee, R.M. |

Carpenter Forem. |

160 |

Lockhart, S.C. |

|

Hudson, Marvin M. |

Hoist Engineer. |

.40 |

Walling |

|

Hudson, R.C. |

Carpenter |

.30 |

Walling |

|

Hudson, Tom |

Pipe Fitter |

.40 |

Walling |

|

Humphrey, James |

Carpenter |

.50 |

Boyles, Ala. |

|

Hyde, H.D. |

Driller |

.40 |

Copper Hill |

|

Hyde, J.H. |

Driller |

.40 |

Copper Hill |

| |

|

|

|

|

Irby, J.C. |

Labor Foreman |

150 |

Alexandria, Va. 241 W. 10th.

St. |

| |

|

|

|

|

Jackson, C.M. |

Carpenter |

.50 |

Walling |

|

Jaco, J.R. |

Carpenter |

.45 |

Smithville |

|

Jeffery, E.G. |

Blacksmith |

.60 |

Gills |

|

Jerngan, C.D. |

Rigger |

.40 |

Walling |

|

Jones, S.J. |

Carpenter |

.45 |

Walling |

| |

|

|

|

|

Kaplan, W.M. |

Transitman |

175 |

Brooklyn, N.Y., 863 deKalb

Ave. |

|

Kell, S.D. |

Ticket Puncher |

75 |

Spencer |

|

Knox, A.L. |

Mule Team Forem. |

.50 |

Stevenson, Ala. |

|

Knox, James L. |

Commissary Clerk |

150 |

Alton Park, Route 6 |

|

Kimsey, Henry |

Blacksmith |

.60 |

Cleveland |

|

Kirksey, Hugo |

Carpenter |

.40 |

Cleveland |

|

Kimsey, J.C. |

Brick Mason |

1.50 |

Sparta |

| |

|

|

|

|

Lawrence, A.J. |

Commissary & Mess Hall |

175 |

Edinburg, Va. |

|

Lewis, J. |

Carpenter |

.40 |

Anderson, Ala. |

|

Lipps, S.M. |

" |

.50 |

Charleston |

| |

|

|

|

|

Marer, J.P. |

Driller |

.35 |

Walling |

|

Martin, F.G. |

Carpenter |

.50 |

Sparta |

|

Martin, R.L. |

" |

.50 |

Rock Island |

|

Martin, Green |

Mechanic |

.40 |

Sparta |

|

Mason, Arthur O. |

Blacksmith |

.60 |

Quebeck (Fine man & Smithy) |

|

Mason, J.S. |

Foreman |

.50 |

Westboro, Mass., 4 John St. |

|

Mason, R.E. |

Rigger |

.35 |

Walling |

|

Mason, Ray |

Tool House Clerk |

.30 |

Quebeck |

|

Marcum, Sam |

Conc. Mixer Forem. |

.50 |

Walling |

|

May, J.W. |

Driller |

.35 |

Twinton |

|

McClure, James B. |

Hoist Engineer |

.60 |

Etowah |

|

McGibbony, Clinton |

Carpenter |

.50 |

Rowland |

|

McCormick, J.B. |

e |

.50 |

Quebeck |

|

McCormick, T.E. |

Labor Foreman |

.60 |

Rock Island |

|

McCormick, W.L. |

Carpenter |

.50 |

Quebeck |

|

McCoy, J.F. |

Blacksmith |

.60 |

Copper Hill |

|

McKay, J.C. |

Driller |

.35 |

Davidson |

|

McKamy, Sam |

Carpenter |

.45 |

Ocoee |

|

Mcmahan, J.A. |

Labor Forem. |

.70 |

Sparta |

|

McMahan, Milton |

Quarry Foreman |

.60 |

Rock Island |

|

McNabb, Harry |

Carpenter |

.50 |

Cullman |

|

McVey, W.G. |

Rigger |

.60 |

Campaign |

|

Mills, J.H. |

Carpenter |

.50 |

Walling |

|

Meredith, J.E. |

Rigger |

.45 |

Walling |

|

Mitchell, Frank |

Carpenter Helper |

.40 |

Rock Island |

|

Montandon, Lester L. |

Truck Driver |

.30 |

Campaign (Was a Deputy

Sheriff) |

|

Mooneyham, L.L. |

Flagman |

.40 |

Rock Island |

|

Mooneyham, I.D. |

Carpenter |

.50 |

Rock Island |

|

Moore, Jack C. |

Mechanic |

.70 |

Rock Island (A-1) |

|

Mooneyham, O.M. |

Rigger |

.40 |

Rock Island (Material

Checker) |

|

Muskelly, J.L. |

Clerk |

110 |

Doyle |

|

Morris, O.T. (Abe) |

Transit Man |

150 |

Nashville, 12 Noel Bldg |

|

Myers, S.A. |

Mill Foreman |

.50 |

Doyle (Saw Mill) |

| |

|

|

|

|

Newton, George |

Mechanic |

.60 |

Sparta |

| |

|

|

|

|

Odell, Algie |

Driller |

.45 |

Doyle |

|

Odell, Elmer |

Driller |

.35 |

Doyle |

|

Orr, J.A. |

Carpenter |

.50 |

Doyle |

|

Owens, G.P. |

" |

.50 |

Sheffield, Ala. |

|

Owens, Kimsey |

Machinist |

.30 |

Parksville |

| |

|

|

|

|

Patterson, N.M. |

Carpenter |

.50 |

Copper Hill |

|

Patton, Roy |

Rigger |

.45 |

Rock Island |

|

Patton, R.M. |

Rigger |

.40 |

Campaign (Hoist Engineer) |

|

Patton, W.J. |

Carpenter |

.55 |

Walling |

|

Patterson, M.H. |

Drill Helper |

.35 |

Mascot |

|

Phifer, C.B. |

Rigger Helper |

.35 |

Doyle |

|

Poe, B.E. |

Driller |

.45 |

Copper Hill |

|

Poe, W.C. |

Drill Forem. |

.70 |

Copper Hill |

|

Poe, W.M. |

Driller |

.40 |

Copper Hill |

|

Posey, M.B. |

Carpenter |

.50 |

East Lake, 33 10th. Ave. |

| |

|

|

|

|

Ramsey, J.H. |

Pipe Fitter |

.30 |

Chattanooga, 614 Cherry St. |

|

Ray, Floyd |

Carpenter |

.40 |

Smithville |

|

Ramsey, J.L. |

Carpenter |

.50 |

East Lake |

|

Rascoe, Edgar |

Rigger |

.40 |

Spencer |

|

Rascoe, Fred |

Rigger |

.50 |

Walling |

|

Reams, Chatham |

Field Engineer |

|

Memphis |

|

Reams, R.M. |

Rodman |

75 |

McMinnville |

|

Reed, Redge C. |

Rodman |

.25 |

Jacksonville, Ill. |

|

Reed, Robert C. |

Electrician |

.35 |

Jacksonville, Ill. |

|

Reed, Walter C. |

Carpenter |

.50 |

Chattanooga |

|

Reese, Aaron |

" |

.50 |

Higdon, Ala. |

|

Richards, C.P. |

" |

.50 |

Walling |

|

Roberts, H.H. |

" |

.40 |

Walling |

|

Robinson, L.D. |

Driller |

.25 |

Twinton |

|

Rogers, W.L. |

Driller |

.45 |

Twinton |

|

Roberts, J.C. |

Carpenter |

.50 |

Campaign |

|

Roller, W.M. |

" |

.40 |

Rock Island |

|

Robertson, J.V. |

" |

.50 |

Elora |

|

Robinson, Frank |

Mechanic |

.65 |

Greenville |

|

Rosenbaum, Earl |

Car Mechanic |

.40 |

Twinton |

|

Ross, A.D. |

Carpenter |

.40 |

Campaign (Hoist Engineer) |

|

Rowland, H.H. |

Foreman |

.40 |

Bone Cave |

|

Rozzell, Frank |

Carpenter |

.50 |

Doyle |

|

Russell, Jerry G. |

Typist, Clerk |

.25 |

Rock Island |

|

Russell, W.L. |

Compressor |

.40 |

Stevenson, Ala.

|

| |

|

|

|

|

Sales, S.B. |

Concrete Forem. |

.60 |

Rock Island (Home -

Chattanooga) |

|

Sanquist, A.C. |

Carpenter |

.50 |

Maryville |

|

Scott, N. |

" |

.45 |

Walling |

|

Seals, A.M. |

Rigger |

.45 |

Walling |

|

Seals, Ed |

Rigger Forem. |

.60 |

Walling |

|

Seals, Ernest |

Pipe Fitter |

.35 |

Walling |

|

Seals, J.R. |

Carpenter Helper |

.35 |

Walling |

|

Seals, L.L. |

Pipe Fitter |

.40 |

Walling |

|

Seals, W.C. |

Mechanic |

.35 |

Walling |

|

Selby, A.A. |

Carpenter |

.50 |

Sparta |

|

Self, C.R. |

Watchman |

150 |

McMinnville |

|

Simmons, Charlie |

Carpenter |

.50 |

Campaign |

|

Simmons, M.A. |

" |

.50 |

Rowland Rt. 1 |

|

Simmons, M.S. |

" |

.45 |

Walling |

|

Simmons, M.S. |

" |

150 |

Manchester |

|

Simmons, S.S. |

" |

.50 |

Manchester |

|

Simmons, W.L. |

" |

.50 |

Campaign |

|

Simrell, E. |

Flagman |

.35 |

Walling |

|

Slack, Tom |

Rigger Forem. |

.60 |

Cleveland |

|

Slack, W.E. |

Rigger |

.50 |

Calhoun |

|

Slatton, Joe |

Rodman |

$3 Day |

Rock Island (A-1) |

|

Sparkman, A.D. |

Carpenter |

.50 |

Doyle |

|

Sparkman, Charlie |

Rigger |

.40 |

Walling |

|

Sparkman, D.S. |

Carpenter |

.50 |

Doyle |

|

Sparkman, Herman |

Rigger |

.35 |

Walling |

|

Sherrill, G.W. |

Carpenter |

.50 |

Chattanooga, 501 Boyton

Terrace |

|

Speck, Elmer |

" |

.50 |

Tullahoma |

|

Standifer, W.C. |

Carpenter Forem. |

.70 |

East Lake, 45 6th. Ave. |

|

Stanley, M.C. |

Drill Helper |

.35 |

Copper Hill |

|

Stenett, V.A. |

Carpenter |

.50 |

Florence, Ala., 522 E. Tuska

St. |

|

Steakley, J.C. |

Guard |

150 |

Spencer |

|

Still, B.M. |

Mechanic |

.50 |

Barnsville, S.C. |

|

Stone, C.S. |

Driller |

.35 |

Dowelton |

|

Stoval, J.A. |

Carpenter |

.50 |

Huntland |

|

Swaah,B.C. |

Hoist |

.30 |

Walling |

|

Swaah, R.L. |

Hoist Engineer |

.50 |

Campaign Joelton |

|

Swift, E.A. |

Carpenter |

.45 |

Walling |

|

Stebbins, F.B. |

Mechanic |

.30 |

Chattanooga, 1706 Holtzclaw

Ave. |

| |

|

|

|

|

Templeton, E.P. |

Carpenter |

.50 |

Quebeck |

| |

|

|

|

|

Underwood, Carl |

Blacksmith |

.60 |

Duck Town |

|

Upchurch, Crockett |

Rigger |

.40 |

McMinnville (Compressor) |

| |

|

|

|

|

Ward, L.H. |

Labor Forem. |

.70 |

Decherd |

|

Ward, Lester |

Commissary Clerk |

115 |

Decherd |

|

Watling, J.G. |

Foreman |

.70 |

Newport, N.H., 26S Main St. |

|

Watters, Clarence |

Hoist Engineer |

.60 |

Morganton, N.C. |

|

Webb, L.R. |

Rodman |

$75 |

Rock Island (Son of john

Webb) |

|

Weese, C.W. |

Carpenter |

.50 |

Epworth, Ga. |

|

Weese, H.L. |

Carpenter Forem. |

.65 |

Epworth, Ga. |

|

Wheeler, Luke |

Mechanic |

.30 |

Spartanburg, S.C. |

|

White, A.L. |

Carpenter |

.40 |

Ocoee |

|

White, W.P. |

Carpenter Forem. |

.70 |

Tasso |

|

Wilcox, J.L. |

Carpenter |

.40 |

Cleveland |

|

Williams, Norman F. |

Transitman |

175 |

Brooklyn, N.Y., 175 Columbia

Hgts. |

|

Wilson, John J. |

Clerk |

110 |

Spencer |

|

Winstead, Ray |

Machinist |

.40 |

Walling |

|

Witt, A.P. |

Carpenter |

.50 |

Quebeck |

|

Witt, A.L. |

Labor |

.30 |

Quebeck |

|

Wolf, Harry |

Master Mechanic |

250 |

Marietta, Pa. |

|

Womack, Clarence |

Rigger |

.35 |

Rock Island |

|

Womack, J.H. |

Carpenter |

.40 |

Rock Island |

|

Womack, J.L. |

Rigger |

.50 |

Rock Island |

|

Wooden, J.H. |

Driller |

.35 |

Mount Pleasant, Rt. 3 |

|

Wright, Robert |

Rigger |

.40 |

Sparta |

|

Wyatt, J.S. |

Carpenter |

.50 |

East Lake, 26:4 4:st/ St. |

| |

|

|

|

|

Not listed. |

labor |

Start .25

Then .275 |

|

Mule Team & Driver |

Hauling by wagon

& grading scoops |

.50 |

|

|